Pool of machinery and equipment

Workshop

The technical equipment used influences the work of a machine builder in a number of ways. The resulting differences in quality, time and cost are quickly apparent to the customer. We are very conscious of this, and continually update our machinery and equipment in step with technical progress and as required by the task.

The powerful HP workstations in our design office are always of recent manufacture, under their manufacturers’ warranty, and covered by on-site hardware support for the event of failure. The risk of projects being delayed by technical factors during the design phase are therefore ruled out almost entirely.

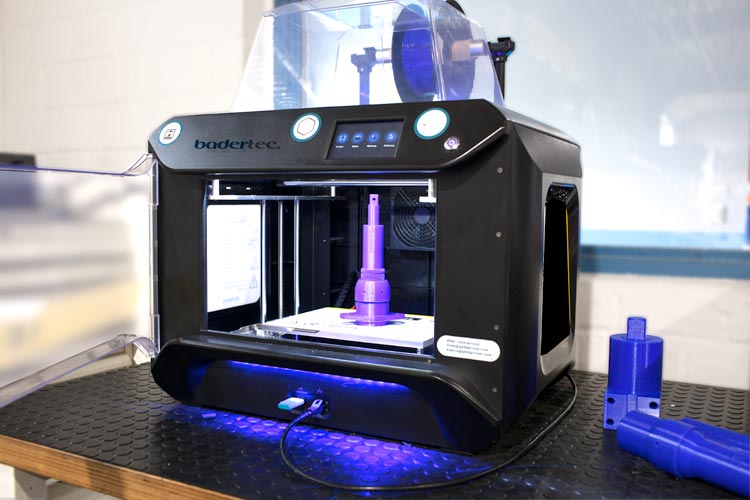

A 3D printer makes feasibility analyses much easier. It enables, for example, a spindle model for integration of screw and nut driving technology to be tested with regard to its ergonomics and collision risk directly on the line within the existing production process.

Software

Software is another area in which we do not compromise. Our engineers design in 3D using the latest version of SolidWorks.