Socket magazines

Master/Slave Socket Selector

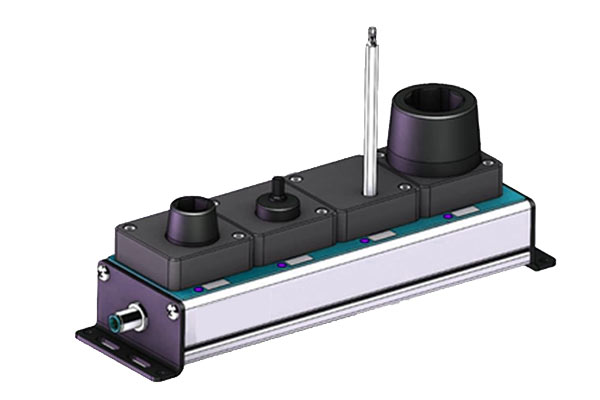

The BTB-4 socket magazine enhances quality assurance and productivity.

Where the same screw or nut driver is used to produce different threaded joints, a risk of confusion exists during socket changes. Badertec GmbH’s socket magazines eliminate such errors completely, permit automated documentation, and increase the productivity of your production processes.

A particularly smart accessory

Socket magazines are often classified as accessories in the screw and nut driving sector. However, they are anything but trivial and have several important functions in assembly involving threaded joints.

The main function of a socket magazine is to eliminate the risk entirely of the wrong socket being selected. Logically, this product is most frequently used in applications requiring alternate use of different sockets or bits on a screw spindle.

The BTB-4 socket selector is a product of our wide-ranging experience in the screw and nut driving sector, and represents a pragmatic and tried-and-tested solution.

Eliminate errors. The operating principle of the socket selector

Each time a tool (socket or bit) is retrieved from the magazine, the sensor integrated in its cell transmits a signal containing the corresponding code to the microcontroller. The microcontroller processes the signal and relays it to the control system. The control system launches a program assigned to the screw/nut driver. The microcontroller also permits selection between different operating modes, such as:

- Linear coding of the sensor signals

- Binary coding of the sensor signals

- Request for a tool by the higher-level system (dig. IN) with monitoring and feedback (dig. OUT)

Retrieval of the tool is signalled to the higher-level control system in the following signal variants:

- Mode 1

Each tool is assigned its own output bit. Retrieval of the tool at sensor 1 sets bit 1 on the output. Retrieval of the tool at sensor 2 causes bit 2 to be set, and so on. Mode 1 can be used with up to 4 slots (with 12 poles). - Mode 2

Retrieval of the tool at sensor 1 causes bit 1 to be set at the output. Retrieval of the tool at sensor 2 causes bit 2 to be set. Retrieval at sensor 3 sets bits 1 and 2. The location of the retrieved tool is signalled by a binary code.

- Mode 3

The higher-level control system requests a specific tool (bits 1 to 4), which is indicated by a flashing LED. Its retrieval is reported back to the control system (bits 5 to 8), and the LED is lit continually. Selection and transmission are also binary.

In all operating modes, the sensors are monitored constantly to ensure that no more than one tool is retrieved at any one time. Should several tools be retrieved, the value 0x0F is output to the PLC.

Worker guidance

The worker guidance function can also be implemented easily by means of BTB-4 socket magazines. A signal to the LED on the relevant socket cell instructs the worker to retrieve the relevant tool. This makes work much easier and increases productivity in manual assembly involving threaded joints.

Two box variants with up to 12 socket cells

Our socket magazines are suitable for bits and sockets with an outside diameter of up to 60 mm.

The basic version of the socket selector is the “master box”. This contains 4 socket cells and can be extended to up to 12 cells by the addition of 2 “slave boxes”. All cells are controlled by the master box through a terminal. This feature optimizes cable management and substantially reduces the number of terminals on the driver controller.