BTA torque arm

A torque arm embodying considerable expertise

Badertec torque arms are the product of many years’ experience in screw and nut driving technology.

Torque is a force that is often underestimated with regard to safety, precision and ergonomics, and coping with it calls for particular knowledge and skills. We are proud to possess these and pleased to be able to apply them to complete a wide range of projects for our clientèle. At the same time, our values include assuming great responsibility for this technology, which has a significant influence on working conditions and human health.

Facilitating work, increasing productivity

During the manual assembly of threaded joints, performing work with the required precision is extremely difficult without the use of suitable handling equipment. In addition, the reaction forces generated in the tool spindle can give rise to chronic occupational diseases in operating personnel, and impair occupational safety.

Badertec GmbH torque arms permit ergonomic and highly productive work at assembly stations. Not only do these handling devices reduce the required physical effort; they also reduce the mental effort required of the personnel during performance of precision tasks.

Scalable and extensible

These handling devices can also be used to extend a range of existing screw and nut driver applications. For example, a sensor system can be fitted to provide more precise position detection, and integration of a screw feeder system can significantly increase the application’s level of automation.

During development of the BTA torque arm, we also provided facility for a large number of screw and nut driving tools from different manufacturers to be fitted, and for the arm to be installed on either the floor or the assembly bench.

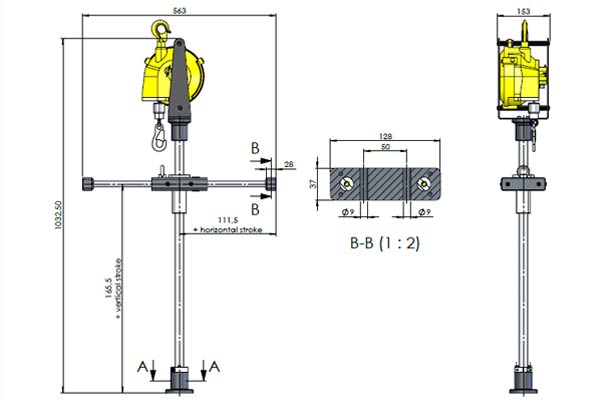

40Nm

- Max. horizontal stroke: 300 mm

- Max. vertical stroke: 380 mm

- Max. rotation.: 340°

- Load level I: 0,5 – 2,5 kg. (EWS-5)

- Load level II: 2,5 -4,5 kg. (EWS-7)

- Dead load: 5,80 kg.

80Nm

- Max. horizontal stroke: 340 mm

- Max. vertical stroke.: 500 mm

- Max. rotation.: 340°

- Load level I: 0 – 4,2 kg. (EWF-9)

- Load level II: 4,7 -10,2 kg. (EWF-15)

- Dead load: 12,4 kg.

150Nm

- Max. horizontal stroke: 365 mm

- Max. vertical stroke.: 525 mm

- Max. rotation: 340°

- Load level I: 0 – 2,8 kg. (EWF-9)

- Load level II: 3,3 -8,8 kg. (EWF-15)

- Dead load: 11 kg.

300Nm

- Max. horizontal stroke.: 460 mm

- Max. vertical stroke: 590 mm

- Max. rotation: 340°

- Load level I: 3,6 – 10,6 kg. (EWF-22)

- Load level II: 10,6 -18,6 kg. (EWF-30)

- Dead load: 19 kg.

500Nm

- Max. horizontal stroke: 475 mm

- Max. vertical stroke: 650 mm

- Max. rotation: 340°

- Load level I: 7,8 – 15,8 kg. (EWF-30)

- Load level II: 15,8 -25,8 kg. (EWF-40)

- Dead load: 29 kg.

1000Nm

- Max. horizontal stroke: 516 mm

- Max. vertical stroke: 800 mm

- Max. rotation: 340°

- Load level I: 9,0 – 19,0 kg. (EWF-40)

- Load level II: 19,0 -29,0 kg. (EWF-50)

- Dead load: 46 kg.